Contract Manufacturing

Specialize in all aspects of harsh environment electronics manufacturing.

While we excel in product design, Riverside’s core strength lies in contract manufacturing, delivering high-quality, tailored solutions and products to meet your requirements.

From PCBs to control panels, Riverside can manufacture the products your company is currently sourcing elsewhere. Provide us with your drawings, CAD files, and BOMs, and we’ll deliver a prompt, accurate quote. With over 90% of our parts sourced in the US and in-house capabilities like PCB assembly, plastic injection molding, and metal fabrication, Riverside delivers high-quality products efficiently and reliably, giving our customers a distinct advantage.

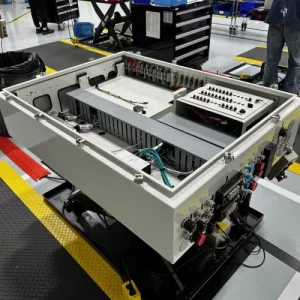

- Box Build Assembly

Riverside excels in Box Build Assembly, providing end-to-end solutions that extend beyond PCB assembly and control modules. From enclosures and wiring to complete system integration, our dedicated team and expansive in-house capabilities ensure precise and reliable assembly tailored to your specifications. With expertise in sourcing quality components and leveraging advanced manufacturing processes, we deliver high-quality, ready-to-use assemblies that meet the demands of even the most challenging applications.

- Plastic Injection Molding

Haitian ZE400

- Qty: 2

- Capacity: 45 Ton

- Shot Size: 1.16 oz

- MIN/MAX Mold Height: 5.91”/12.6”

Haitian ZE600

- Qty: 2

- Capacity: 67 Ton

- Shot Size: 1.1 oz

- MIN/Max Mold Height: 5.91”/14.57”

Haitian MA4700III

- Qty: 2

- Capacity: 528 Ton

- Shot Size: 45.7 oz

- MIN/MAX Mold Height: 12.6”/30.71”

- Metal Fabrication

Amada M 1245 CNC Shear

- Capacity: 48.82” X 3/16”

- Blade Length: 52.76″

- 75 SPM

Amada RG35 Pressbrake

- Capacity: 38 Ton x 4’

- 48″ OA Length

- 3.94″ Max Stroke

Amada Pega 24 Station CNC Turret

- Capacity: 22 Tons

- Sheet Size: 40”x40”

- Turret Stations: 20

Bliss C-60 - 1990

- Tonnage: 60 Tons

- Bed W: 21”

- Bed L: 32”

- Stroke: 4”

Bliss C-60 - 1989

- Tonnage: 60 Tons

- Bed W: 21”

- Bed L: 32”

- Stroke: 4”

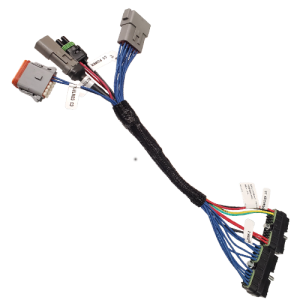

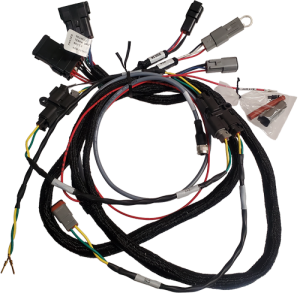

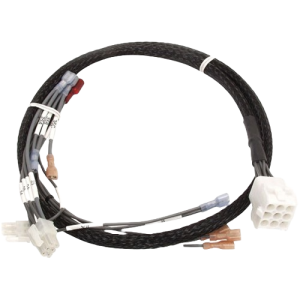

- Wire Harnesses & Cable Assemblies

With Riverside’s extensive internal capabilities and our collaboration with Advanced Harness—a partner company based in Logansport, IN—we provide comprehensive support for all your wire and cable harnessing needs.

- Other Solutions